Replacing excavator chains and sprockets requires a set of specialized tools and equipment to ensure the job is done safely and effectively. Here’s a comprehensive guide on the equipment needed for this task:

- Personal Protective Equipment (PPE): Before starting any maintenance work on heavy machinery like excavators, it’s crucial to prioritize safety. Wear appropriate PPE such as gloves, safety goggles, steel-toed boots, and a helmet to protect against potential hazards.

- Hoisting Equipment: You’ll need a reliable hoist or crane to lift heavy components such as the excavator tracks and parts of the undercarriage. This equipment ensures safe handling and prevents injuries during the replacement process.

- Torque Wrench: A torque wrench is essential for accurately tightening bolts to manufacturer-recommended specifications. Proper torque ensures the components are securely fastened without the risk of over-tightening, which could damage threads or components.

- Impact Wrench: An impact wrench is invaluable for quickly removing and installing bolts and nuts. It provides high torque output with minimal effort, making it ideal for dealing with stubborn fasteners often found on heavy machinery.

- Track Press: A track press is used to remove and install the track chains on the excavator. It applies controlled pressure to press the pins in and out of the chain links without causing damage. This tool is essential for safely handling the heavy-duty tracks.

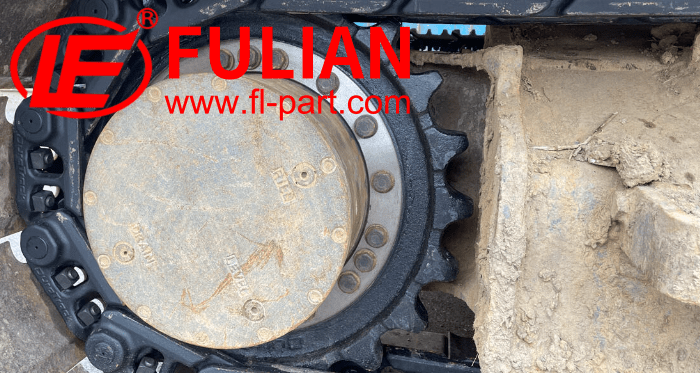

- Sprocket Puller and Installer: Specialized tools for removing and installing sprockets are necessary due to their size and weight. A sprocket puller helps to safely detach the old sprocket from the drive shaft, while a sprocket installer ensures precise alignment and installation of the new sprocket.

- Track Roller Frame: A track roller frame supports the undercarriage while the tracks are removed. It provides stability and prevents the excavator from tipping during maintenance. This tool is crucial for safely accessing and working on the undercarriage components.

- Grease Gun: Proper lubrication is essential for extending the life of new chains and sprockets. A grease gun allows you to apply grease to the moving parts, ensuring smooth operation and reducing wear and tear.

- Cleaning Tools: Before installing new components, thoroughly clean the undercarriage area to remove dirt, debris, and old grease. Use brushes, rags, and cleaning solvents to ensure a clean surface for optimal performance of the new chains and sprockets.

- Manuals and Documentation: Always refer to the excavator’s maintenance manual and manufacturer’s guidelines for specific instructions and torque specifications. This ensures that the replacement is done correctly and maintains warranty compliance.

- Workshop Space: Adequate space in a well-lit workshop or maintenance bay is essential for safely performing the replacement. Ensure there is enough room to maneuver the equipment and store tools and parts securely.

- Assistance: In some cases, replacing excavator chains and sprockets may require assistance from trained personnel or a qualified mechanic. They can provide expertise and ensure that the replacement is carried out efficiently and safely.

By utilizing these tools and equipment, you can effectively replace excavator chains and sprockets, ensuring optimal performance and longevity of your heavy machinery. Always prioritize safety and follow recommended procedures to minimize downtime and maximize operational efficiency.

Fulian Operation Team

2024.08.03